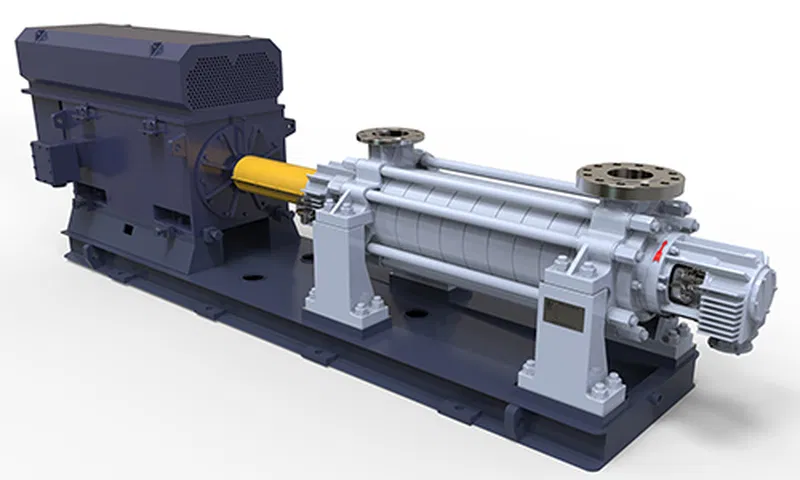

Multi-stage, horizontal, radial split; foot or centerline mounting, support at both ends. The CFD fluid analysis software system is used to design high-efficiency hydraulic power, and the special mid-stage application makes the overall efficiency of the pump reach the international leading level. Forged pressure parts, precision casting flow parts, special friction ring surface treatment process, reasonable bearing arrangement and lubrication ensure the safety and reliability of the pump and long-term operation requirements.

PARAMETER

| HBS | ISO | US |

| Design | ISO 13709 | API 610 |

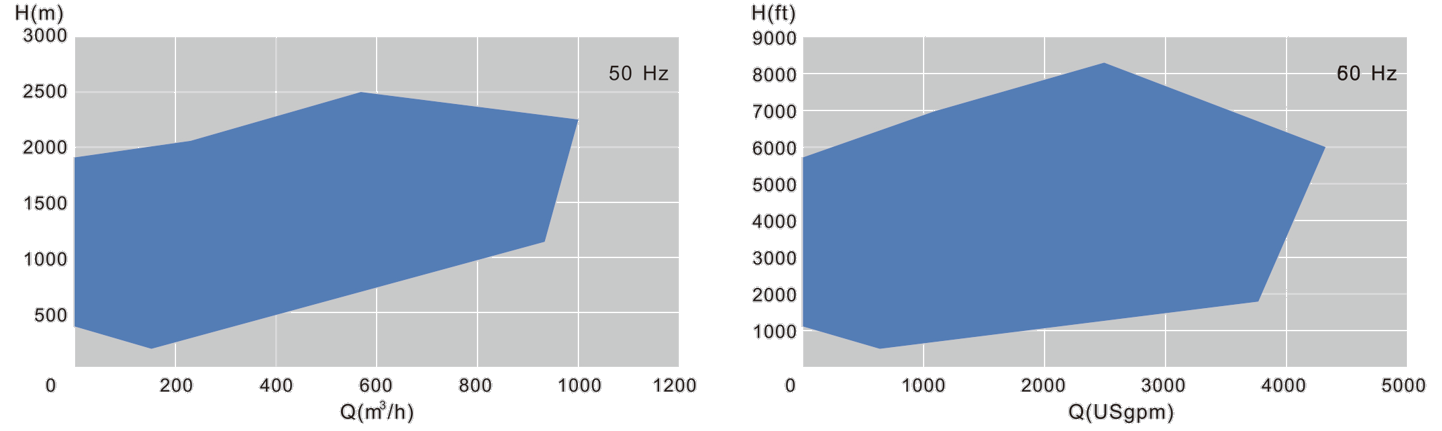

| Capacity | Up to 1000 m3/h | Up to 4400 Gpm |

| Head | Up to 2500 m | Up to 8200 feet |

| Temperature Range | -80 ~ +210 Dec C | -170 ~ +410 Dec F |

| Pressure Range | Up to 270 bar | 3900 psi |

| Material Range | Carbon Steel, SS, Duplex, Super Duplex, Hast alloy | |

| Nozzle Direction ( suc / dis ) | Top / Top | |

| Motor Sync. Speed | 1000 / 1500 / 3000 rpm | 1200 / 1800 / 3600 rpm |

| Options | Double suction is avaliable | |

| Flange Standard | ANSI / HG / DIN / JIS | |

PERFORMANCE